AIROPTIC

Experts in real time gas analyzers

Airoptic Sp. z o.o. is an ISO 9001:2015 certified high-tech company founded in Poznan, Poland. Airoptic manufactures high performance tunable laser analyzers for industrial process control, emission monitoring as well as safety and security applications. Airoptic provides in-situ, extractive and open path systems analyzer configurations which can be tailored to match specific customer needs.

Thanks to unique in-house sensing technology Airoptic has pioneered in-situ multi-gas detection technology utilizing multiple semiconductor lasers which allowed to overcome limitations of traditional single laser TDL systems.

Power Industry

GasEye analyzers can be applied in several places in a power plant starting from a coal silo (CO measurement), through boiler optimization (CO+O2+CH4+H2O) to emission control (NO, NO2, NH3, SO2, SO3) and CEMS (HCl, NH3, HCHO, HF). Both in-situ as well as extractive analysis is possible.

Chemical Industry

Steel Industry

Wood and Paper Industry

Products for

GasEye Cross Duct SG

GasEye Cross Duct Single Gauge analyzer provides a sensitive and selective in-situ measurement of one selected gas component directly in a process. This analyzer provides an unattended 24/7 operation scheme, short response time, and requires almost no maintenance after installation. With IP66 protection analyzer can operate in a harsh environment in ambient temperature ranges from -20 to 55 deg C. It is also suitable for operation in hazardous areas.

Products for

GasEye Cross Duct MG

GasEye Cross Duct Multi Gauge analyzer provides sensitive and selective in-situ measurement of several gas components directly in a process. This analyzer provides unattended 24/7 operation scheme, very short response time and requires almost no maintenance after installation. With IP66 protection analyzer can operate in harsh environment in ambient temperature ranges from -20 to 55 deg C. It is also suitable for operation in hazardous areas.

Products for

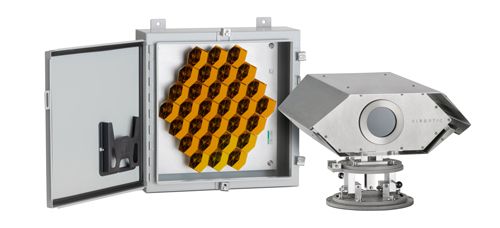

GasEye Extractive

GasEye extractive analyzer provides sensitive and selective extractive measurement of gas components. This analyzer provides unattended 24/7 operation scheme, short response time and requires almost no maintenance after installation. As standard the analyzer comes with a 19-inch rack type or wall mounted IP66 enclosure however various other types of enclosures are available on request. It is also suitable for operation in hazardous areas. The analyzers can be equipped with heated cells for hot-wet analysis and/or a built-in pump for extraction of a sample from the process.

Products for

GasEye OpenPath

GasEye open path analyzer provides sensitive and selective measurement of gas components directly in atmosphere. This analyzer provides unattended 24/7 operation scheme, short response time and requires almost no maintenance after installation. Both monostatic and bi-static versions are available. Monostatic version consists of a combined transmitter-receiver unit and retroreflector and is suitable for long distances operations (up to 1 km). Bi-static version consists of a separate transmitter and receiver units and is suitable for moderate distances (up to 100 m).

Years of experience

Gas combinations

%

Maintenance free

Continuous operation

Experience

25-year experience in design of tunable laser analyzers

We have been involved in the developing of tunable diode laser gas monitoring instrumentation and spectrometers for more than two decades, including the development of a wide range of gas monitoring instruments for applications in industrial process analytics and in medical analysis. Our solutions have been proven in field for more than 2 decades in thousands of pieces worldwide.

This experience allowed us to design and build the GasEye analyzer which combines state-of-the art spectroscopy solution with a novel analyzer platform. From the very beginning we have been constantly working on user friendly solutions to allow easy installation and less maintenance effort.

All GasEye components (optics, mechanics, electronics, firmware and software) are designed and built in-house by our highly specialized personnel. We deliver an uncompromised performance and quality to our customers. Thanks to modular design of the GasEye we are able to provide tailored solutions to address even most specific customer needs, starting from a special calibration in exotic gas matrices to completely customized hardware solutions.

High Performance

The GasEye – a versatile high performance gas analyzer platform

The GasEye is a maintenance free gas analyzer, designed for emission monitoring and process control with 24/7 continuous operation. All GasEye series analyzers are equipped with autocalibration features based on a reference gas assuring no zero and span drift throughout analyzer lifetime. There is no need for sample conditioning, does not exhibit zero or span drift, and no field calibration is necessary. Our technology allows measurement from ppb to ppm with large dynamic ranges and responding in less than 0.1 second.

GasEye series was designed without compromises to deliver highest performance available on the market. Our analyzers deliver lowest limits of detection thanks to a unique design that practically eliminates optical fringing effects (also called etalon effects) – which is a limiting factor in a TDL technology.

Multi-Gas capability

The GasEye – Multi-laser multi-gas capability made simple

The GasEye analyzer allows combination of several lasers in the analyzer which allows not only to reduce a cost and form factor of the analyzer itself but also significantly simplifies process interface, commissioning and maintenance in case multi-gas analysis is required. With our multi-gas analyzer, it became possible to provide purely TDL based solutions to industrial processes where normally traditional single laser TDL analyzers had to be accompanied with extractive NDIR analyzers e.g. desulfurization and denitrification processes in a power plant.

With only one pair of flanges compatible with most of the existing single gas analyzers, the GasEye can be installed using the existing process infrastructure thus making transition from single to multi-gas analysis an easy job.

Airoptic Knowledge

Cooperation

We operate all over the world

Airoptic has distribution partners all over the world. We make sure the customers all over the globe will receive a good support by a local partner nearby the installation site. We frequently organize trainings and workshop at our facility to ensure also a quick and efficient service of our analyzers in field.

“The number of GasEye analyzers have been operated and maintained well since the installation was completed and customers are satisfied of the performance than they ever expected. Multi-gas analyzers from Airoptic are truly a novel solution among other TDL analyzers available on the market.”

“Sodra Cell Morrum paper mill has installed 2 pc of GasEye for CO-measurement after Biomassboiler (bark) and a steamboiler before ESP since September 2017. The sensors has been used both as a part of safety system to protect ESP and for process control of the boiler. The sensor systems have so far operated to our satisfaction.”

“M&C TechGroup North America has installed GasEye cross duct and open path instruments in a wide variety of applications in many different industries. The technical support of Airoptic is unmatched in the TDL analyzer field and the multi component monitoring capability inside a single instrument offers many unique solutions to provide optimal solutions to our customer base.”